Description

Detail

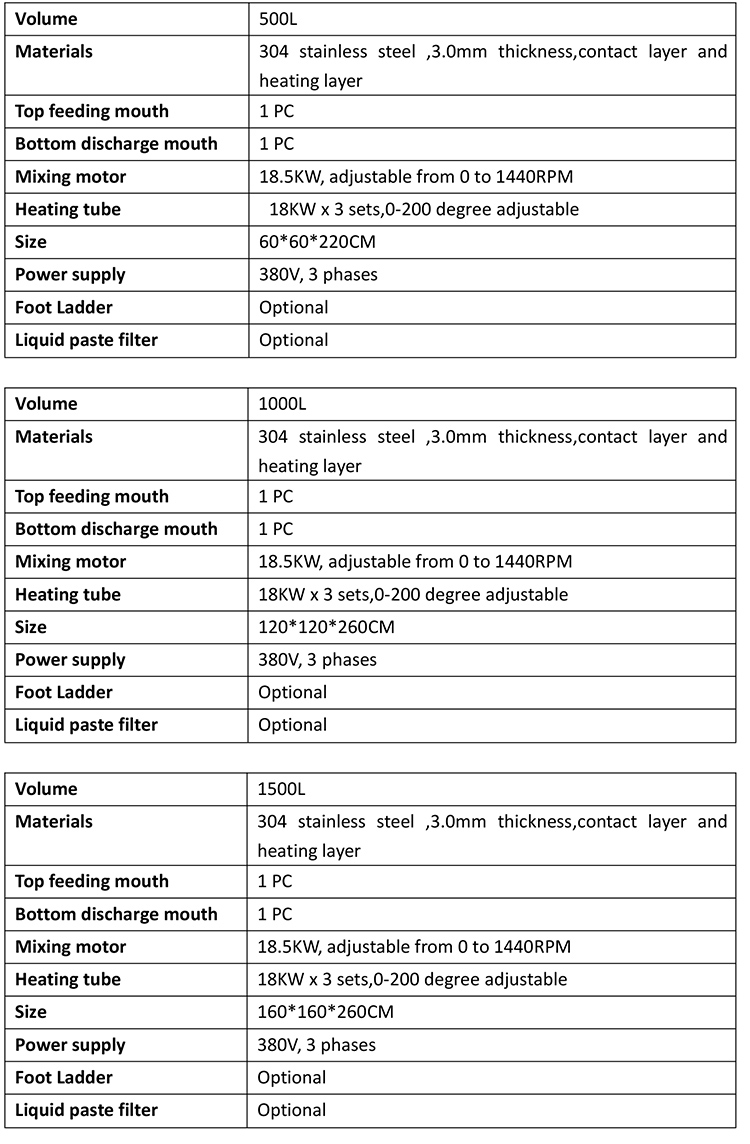

The mixing tank mainly consists of motor, reducer, stirring tank, stirring tankcover, mixer, support,transmission, shaft sealing device , Electric control boxand other components,but also according to process requirements configurationelectric heating and steam heating interlayer and related devices, but also addcooling device. Mixing tank and mixing tank cover can be sealed flange connection or welding connection. Mixing tank and stirring tank cover can beequipped with feed discharge port, observation window, temperature measurement pressure port, steam fractionation, safety vent and other processtube holes on request. This machine can be used as standalone production, massproduction of materials,can also be connected into a full set of automated production lines, the front of a variety of liquid, powder and powder quantitativeplus local, mixing and mixing completed, and then connected to the automaticquantitative filling, Sealing, 1abeling production line(small batch production canbe connected semi-automatic filling machine).

Feature

- The whole polish compound blender is a double-layer vertical type, with an upper flat top and a single-side flip cover, a lower head structure, a bottom discharge port, and three columns with round feet on the ground (300mm above the ground).

- The material contact surface of the tank body is made of 304 stainless steel 3.0mm thickness, the heating layer is 304 stainless steel 3.0mm thickness, the inside and outside of the tank are mirror polished, the top single-sided flip cover (for feeding and viewing), 1 inch feeding mouthon the top, one 2inch discharge mouth at the bottom.

- The mixing motor is 18.5KW, the stirring speed is adjustable from 0 to 1440 per minute, the stirring structure is a dispersion plate, the stirring shaft is fixed by the shaft sleeve, and the material contact material is 304 stainless steel, which can be disassembled.

- The bottom of the heating layer is equipped with 3 heating tubes, the heating power is 18KW, the equipment is equipped with a thermostat (temperature adjustable) and a stainless steel control electric box wiring can work.

Parameter

Application:

- Mixing tank is widely used in the production of liquid paste materials inpharmaceutical, food, chemical glue, polymer technology and new material industries. It can be used to mix, homogenize and reconcile materials Add somepowder and pellets, provided the final product is a liquid or paste).

food and beverage industry: reconcile oil, seasoning sauce, fruit juice, alcohol,dairy products, etc. - Daily chemical industry: shampoo, milk foam, cleanser, sunscreen, liquidlaundry detergent, disinfectant hand sanitizer, detergent , Skin care cream,toothpaste, hair conditioner and so on.

- The pharmaceutical industry: oral liquid, ointment, emulsion, Vaseline,cleaning and disinfecting lotion and other liquid paste materials.

- Industrial chemical industry: white latex, adhesive, paint, chemical Cleaningagent, chemical liquid additive, chemical solution, new material of polymer liquid,etc.

Relative post: How do you make a polish compound?