Description

Operation

Parameter

| Process buffs OD (big version) | OD 150-600mm |

| Process buffs OD (small version) | OD 60-450mm |

| Process buffs ID | Plane buffs: 8-20mm,

Airway buffs: 80,130,180,230mm Customized |

| Knife belt wheel diameter | 490mm |

| Belt knife total length | 3150mm |

| Produce speed | 2-3 buffs/ 20 second

depend on buffs thickness and OD |

| Machine size | 1700x1100x1550mm |

| Wood case packed size | 1800x1200x1750mm |

| Main motor power | 2 KW |

| Working voltage | 380V, 3 phases or customized |

| Air pressure | 6KG or 0.4 MP |

| Consumable items | Knife belt,grind wheel |

Feature

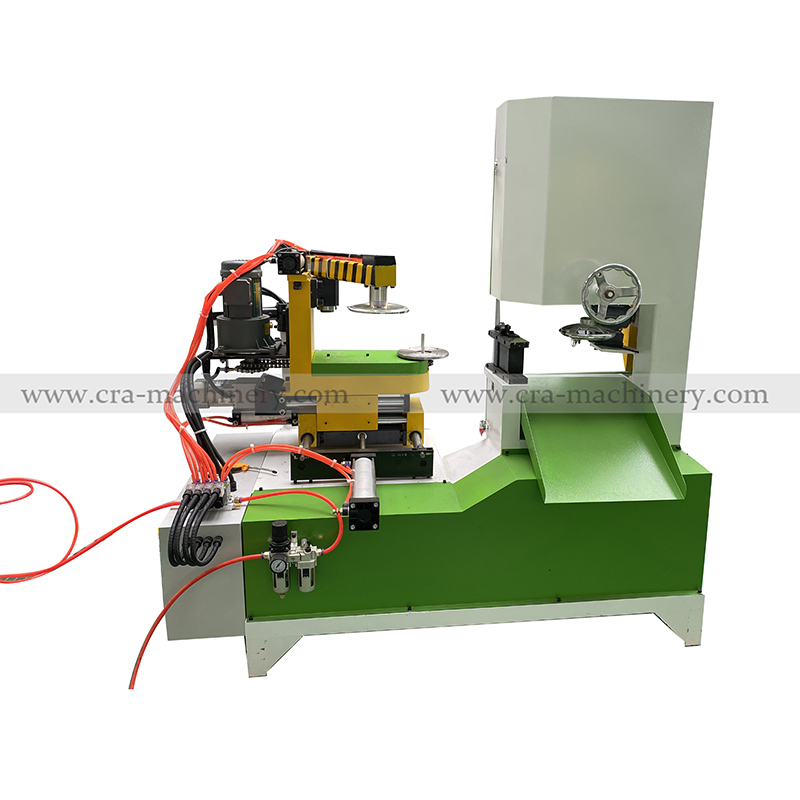

- CE certificated machine. Sisal and cotton buffs edge cutting machine made by heavy steel plate, have enough intension and stability, use for fixing the saw and the equipment to tight the saw.

- Belt knife made by imported materials, length 3150mm.Knife sharpener made by 2 motors and adjustment rack, for sharpening the knife

- Knife rest: made by alloy-steel plate, have enough intension and stability, ensure the verticality of cutting face between belt knife and the buff wheel.

- Working bench: use for automatically feeding, adjustment of sizes of the wheel.

- Main parts:Mechanical transfer arm,Feeder,Pneumatic parts, Motor, Speed controller.

Operation Process

- Put buffs edge trim machine on smooth ground, connect to 380V 3 phases 4 wires power supply, and 0.4 MP air source.

- Press the START button, ensure the knife belt rotate at the clockwise direction.

- Loose the handle screw beside the ruler, by operating the Forward button and Retreat button to adjust size of the buffing wheel, and using Knife Forward button and Knife Retreat button the knife, lock the screws after finishing adjustment.

- Cutting: After putting on the wheel , Press the Press button, machine start the Automatic control system(cylinder press the wheel—cutting—setting the rounds figures—wheel retreat automatically—cylinder goes up—finished cutting)

- Cutting speed setting: You can adjust the rotate speed depend on different materials buffing wheel to achieve the highest efficiency.

- Knife sharpening