Description

Operation link:

The market condition of buffing and polishing wheel manufacturers is getting worse, because the fierce competition the industry profit margin is extremely low. So the rising labor cost became their greatest concern, CRATOOLS SG01M automatic spiral sewing machines just came under this background.

Many buffing wheels manufacturers are searching for machines not only to make the production process more automation, but also to lower the production costs (reducing number of employees). We devote ourselves to develop highly automated industrial sewing equipment base on the concept of “One-Worker-Multiple-Machine (OWMM)”, for maximizing efficiency and controlling costs.

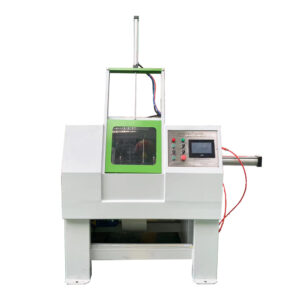

SG01M Buffing Wheel Spiral Stitch Sewing Machine: it is affordable semi automated sewing equipment for manufacturers of buffing wheel and polishing wheels.

Installation link:

Feature

- Specially for thick material adopts single-needle and oscillating shuttle, upper and lower synchronized feeding, forms 2-thread lock stitch. It has been adjusted in specialized according to the sewing requirement of round sisal and fabrics buffing wheel.

- It is suitable for sewing sisal and fabrics buffing wheel with super-thick, medium and thinner material. No skipping stitches when sewing thick material and no puckers when sewing thin material.

- The manual presser could be pulled in forward, backward, left and right directions; it could fix the partial of sewing material. For packing products with dust-proof strip, it could sewing that in changing needle position and three kinds of parts.

- It has lifting feeding tooth and alternation presser. This structure could keep the upper layer and lower layer in same position without move. when sewing smooth viscous and super-long products under any length of stitch size.

- The connecting-bar take-up mechanism could improve the speed of arm shaft,reduce the noise. guarantee the quality of whole machine and prolong the service life.

Parameter

| Speed of sewing | 800 s/min |

| Needling distance | Standard is 5mm, other distance can be customized |

| Power of electric motor | 550W 1400r/min |

| Presser lifting(buffs thickness) | 18-25mm |

| Operating space | 200*420mm |

| Model of needle | 7CM*(200/230/300 NM) |

| Net weight of head section | 78Kg |

| Travel of needle pole | 58mm |

Relative Machine

Thick Buffs Polish Buffing Wheel Sewing Stitching Machine