Description

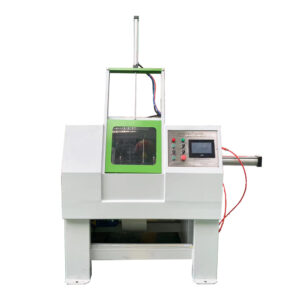

CRA-800 Model Airway Buffing Wheel Making Machine is used to form the airway buffing polishing wheel, also called as Ventilated Sisal Buffs, airflow buffs, bias airway buffs. Available for materials of soft or harden treated fabric, sisal etc. Before using this machine, you should prepare bias fabric or sisal, and iron claw or plate according your favor. Bias fabric making you can use our CRA-500 Bias Fabric Cutting And Rolling Machine For Airway Buffing Wheel.

And to make a ready wheel, after this forming machine, two more processes should be done-Pressing and cutting.

Pressing you can use our CRA-600 Buffing Wheel Pressing Machine and

Edge cutting use CRA-700 Knife Belt Buffing Wheel Edge Cutting Machine.

Advantage:

- Available for airway buffs from 200-600 mm diameter.

- Available for materials of soft or harden treated fabric, sisal etc.

- Available for almost all hot sale center,Iron claw 2 inch, 2.5 inch, 5 inch, or Iron plate with round hole, hexagon hole.

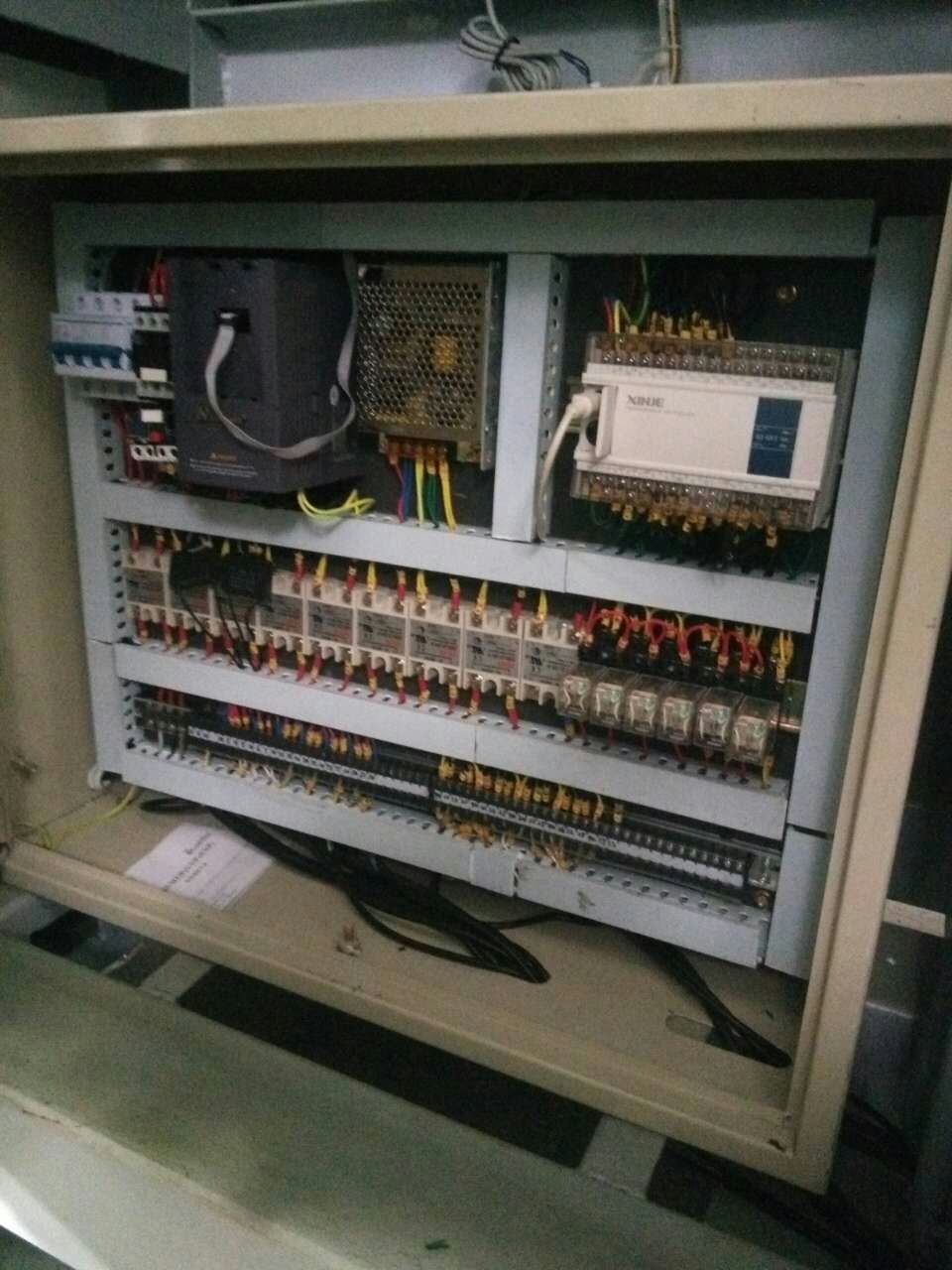

- Each control, full automatic, only need one worker to operate.

- High production rate: Maximum 5000 PCS per day .

- Interface and language in English.

- Offer free training on machine and life time consultant.

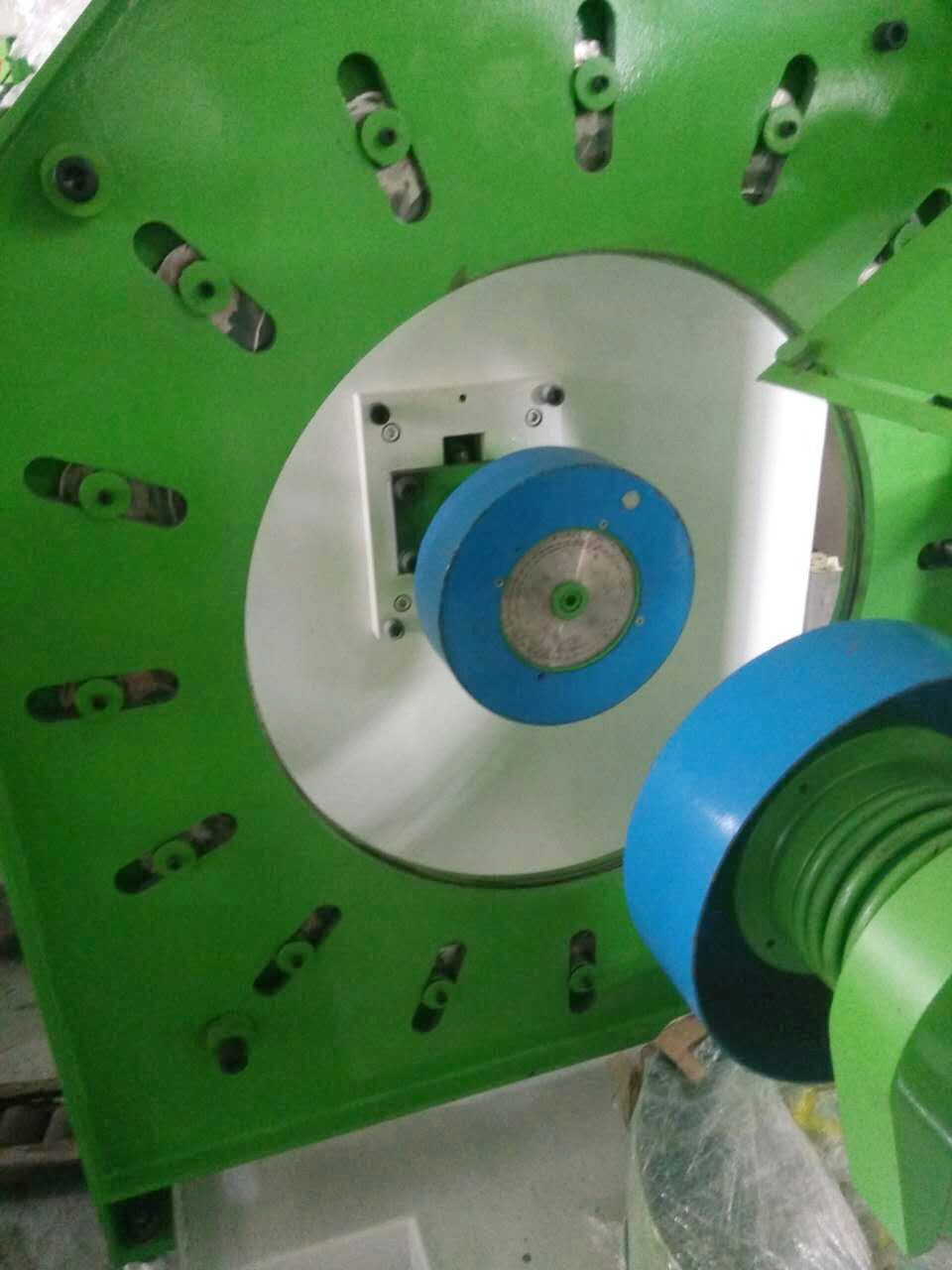

Structure of airway buffs produce machine

- hydraulic system 7. right cylinder

- left trestle 8. right Spandex

- left cylinder 9. circuit board

- pressure gage 10. Turntable right

- upper Spandex 11. cutter

- control panel 12. Turntable left

Parameter

| Parameter | Model 800 Airway Buffing Wheel Making Machine |

| Size(mm) | 2.8m*1.8m*1.6m |

| Voltage AC(v) | 380V three-phase four-wire(customized) |

| Power(kw) | 6 |

| RPM of Batching | Adjustable |

| MAX dia of buff(mm) | 600 |

| Min dia of buff(mm) | 200 |

| Finishing pressure(map) | 7 |

| Moulding press(map) | 7 |